Plastics are everywhere. They are strong, durable, lightweight, easily formable – and cheap. Modern society could not function without them. However, our success at engineering such useful materials has created a systemic problem, with more than 10 megatonnes of plastic leaking to the environment and into the oceans annually. The problem is so pronounced that researchers at the Stockholm Resilience Centre are considering it as a planetary boundary threat.

Biodegradable bioplastics, along with their natural fibre composites, are seen as pivotal for a transition to a more sustainable plastics economy. The opportunity for Australia is very large: while the bioplastics and biocomposites industry in Australia is still emerging, Australia has an abundance of the requisite natural bioresource raw materials for the manufacture of bioplastics and biocomposites. A new $13 million Australian Research Council (ARC) Industrial Transformation Training Centre for Bioplastics and Biocomposites, based at the University of Queensland’s School of Chemical Engineering, has been established to advance the transition. The training centre is a partnership between the University of Queensland and QUT, alongside the Queensland Government, Kimberly-Clark Australia, Plantic Technologies, Australian Packaging Covenant Organisation, Minderoo Foundation and the City of Gold Coast.

The Centre supports the training and development of 19 PhD candidates, along with four early career researchers. Much of the research focuses on product development. It has been estimated that biodegradable, bioderived plastics could directly substitute for nearly a third of petroleum-based polymers. Biodegradable plastics and some composites are already widely used in disposable items such as packaging, containers, straws, bags and bottles. Packaging, particularly thin films, represents more than 50% of the global plastics market, and there is a serious issue with contaminated films that cannot be effectively recycled and are sent to landfill or escape into our environment. Therefore, one of the key areas of global interest is in the development of flexible films for packaging that are truly biodegradable under ambient conditions, opening the door to a wide range of waste management options, including digestion for biogas production.

The copolymer polyhydroxybutyrate-valerate (PHBV), which is the most widely commercially available biopolymer in the polyhydroxyalkanoate (PHA) family, is an excellent candidate for such applications. PHAs have high water barrier properties along with reasonable gas barrier properties, which together help extend shelf life of packaged products. And, above all, PHAs are truly biodegradable in ambient conditions; other plastics currently used to make thin films either don’t biodegrade or only biodegrade under a limited set of conditions. But PHBV has an extremely low melt strength and is very challenging to film blow and thermoform due to its flow performance characteristics; it undergoes strain thinning during extensional flow. This is suspected to be due to a lack of entanglements that PHBV exhibits in the melt. In particular, the low melt strength of PHBV limits its applications to products that are produced by processing methods such as extrusion, which produce thin strands or thick sheets, and injection moulding, which can produce products like meat trays or punnets.

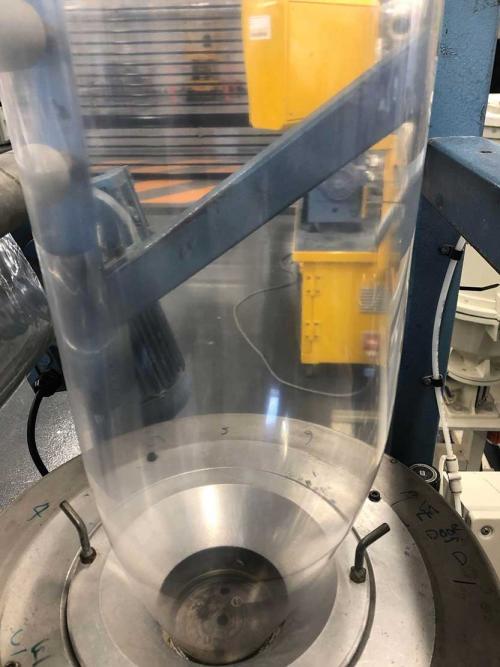

Enter PhD candidate Sam Lawless. In Sam’s PhD project he has modified PHBV to facilitate strain hardening, making it amenable to film blowing. He has already used the modified polymer to blow films as thin as about 40 micrometres, which is the desired thickness for plastic films in many film applications. This new PHA formulation increases the suite of potential commercial products that can be made from bioderived and truly biodegradable plastic. But still more work is to be done to now improve the mechanical properties, particularly the toughness, of the PHA films. Sam is now teaming up with Dr Katrin Kockler and two new PhD candidates to tackle this problem.

One of the Centre’s industry partners, Plantic Technologies, is an international innovator in starch-based barrier materials, offering a wide range of bioplastic packaging (principally used for thermoformed packaging, films and pouches) derived from starch, as an alternative to conventional plastics packaging. This innovative material, developed initially in partnership with the University of Queensland, CSIRO and other institutions, has positioned Plantic as a global leader in the field. Professor Pete Halley and Dr Emilie Gauthier are now leading research to understand and improve the key processing and physical properties of the starch-based films as well as investigating other packaging applications. This work focuses on the development of technologies to address the challenge of producing high-performing thin films, while maintaining the barrier performance of this 100% biodegradable starch-based sheet, given that the high oxygen barrier is crucial for multilayer food packaging applications to extend shelf life. This will in turn reduce food waste, helping to reduce the greenhouse gas emission through materials supply, processing and end-of-life options.

Beyond packaging, there is significant opportunity for immediate application of bioplastics and biocomposites in environments where collection and recycling of products is near impossible (e.g. agricultural applications, where biodegradable mulch films and encapsulants or coatings for fertilisers and other agrichemicals that are truly biodegradable in on-farm soil environments would not have to be removed and disposed). An advantage offered by biodegradable polymers is the opportunity to control the release of bioactives without leaving unwanted, non-degradable residues. But tight economic margins for products such as fertilisers limit the maximum polymer content of controlled formulations to <10 wt%. Achieving sustained, long-term release profiles is then challenging when utilising thin, naturally biodegradable polymer coatings. Further, water ingress leads to granule swelling, so significant polymer elongation is required to avoid rupture. Dr Ian Levett is building in-house coating equipment for spray coating of fertiliser granules in order to investigate release profiles from a suite of biodegradable polymer-coated fertilisers. In parallel, he is developing mathematical release models, accounting for diffusion processes, granule swelling and polymer degradation to guide materials selection and tailor formulation design. A newly joined PhD candidate, Sumedha Amaraweera, will build on developments in this space.

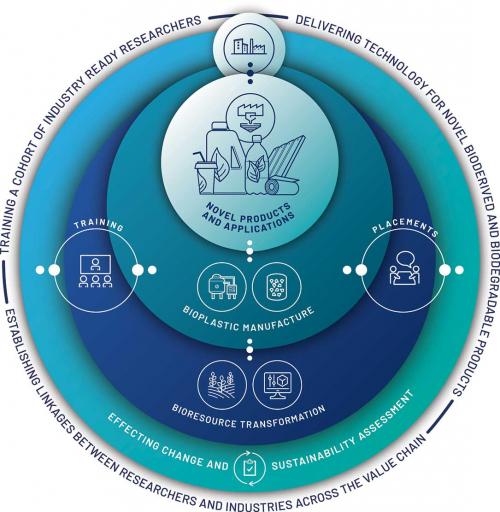

But the Centre is not only focused on overcoming technical challenges. Plastic pollution is a wicked problem, meaning the Centre must perform leading-edge research on product development but with a holistic focus. So, in addition to core polymers/materials expertise, the Centre pulls together experts from across the biomaterials value chain, recognising the critical importance of social, economic and environmental issues in delivering a viable transition strategy. Research theme 1 will deliver advances in technology for bioresource transformation, including detailed understanding of the opportunities afforded to supply chain integration. Research theme 2 considers bioplastic manufacture, including addressing engineering constraints associated with scale-up of technology. Coupled with this, a clear objective is to utilise new and readily available bioplastics and biocomposites in the development of novel products and applications (research theme 3). These activities are all underpinned by research into effecting change and sustainability assessment, which will lead to a better understanding of in-use and post-use stability and lifetimes, technoeconomic and life cycle assessments of these alternative products, and strategies for addressing social and policy barriers to their implementation (research theme 4).

For example, PhD candidate Tracey Read is studying what happens when these so-called ‘greener alternatives’ end up in waterways. Tracey says, ‘We know most people think all biodegradable plastic is fast at biodegrading in any environment, but that is unfortunately not the case’.

Tracey is working with Professors Bronwyn Laycock and Paul Lant in the University of Queensland’s School of Chemical Engineering, to examine how form and processing of three different types of biodegradable plastic (PHA along with polylactic acid (PLA) and polybutylene adipate terephthalate (PBAT)), commonly found in everyday packaging and waste bags, break down once in the water. The bioplastic samples have been submerged at aquatic environments across south-east Queensland, representing the locations to which waste plastics often travel. Tracey is hopeful the research will be used to develop materials and products with reduced lifetimes and risk to marine life in the event the biodegradable plastic ends up in waterways. ‘There is a lot of research on what happens to biodegradable plastic in soil, compost, on land, and in landfills, but we actually don’t know what happens when these materials enter the marine environment’, Tracey says. The project has been dubbed the ‘Epic Field Trial’. You can follow along by searching @EpicFieldTrial on Instagram.

PhD candidate Hannah Bennett, who has just joined the Centre, is looking at bioplastics and responsible innovation. Bioplastics have exciting potential as an alternative to fossil-fuel-based plastics but, as with most new technologies, social acceptance and trust are fundamental to their widespread acceptance. It is important to identify public concerns, expectations and perceptions in order to support the responsible development of this technology. Hannah – under the supervision of Dr Severine van Bommel, Professor Emeritus Helen Ross (social scientists in the University of Queensland’s School of Agriculture and Food Science) and Dr Anya Phelan (with the university’s Business School) – recognises a wide range of possibilities in this subject area, but, given Hannah’s background in sociology, cultural theory and design, is focused on the field of packaging. Hannah is excited by the connections with industry the centre offers, including a lengthy industry placement. Hannah says ‘Transitioning to bioplastics involves more than just lab-based materials engineering. Plastics (both fossil- and bio-derived) exist within complex systems of stakeholders and user behaviours. Only by considering these systems can we create bioplastics that function as intended within the complexities of real-world use. My role within the centre is to examine these systems and find bottlenecks that may hinder the mainstream adoption, proper integration, and sustainable development of bioplastics’.

The plastics system is indeed complex, with a wide range of stakeholders. It is hoped that by teaming material scientists and engineers with business experts, biologists and social scientists, the Centre can perform the leading-edge research with a holistic focus that’s necessary to underpin Australia’s transition to a globally significant player in the rapidly growing bioplastics and biocomposites industry.