The materials economy has thrived thanks to the contribution of materials to the lives of billions of people on Earth. For a materials-related economy to continue to flourish, the materials sector must use every opportunity to develop a more circular concept to consumption (capitalism is not necessarily a solution), especially with current rapid rates of technological change and demand for new applications. Landfills are rapidly filling with discarded electronics, the oceans are littered with plastic, it is becoming harder to secure the supply of clean water, and the environmental impact of climate change is devastating.The tools, processes and discovery schemes used by chemists and materials scientists today to address these problems are faster and more powerful than ever. We can visualise matter in extreme detail down to the atom scale, run accurate computer simulations, observe materials’ behaviour in real time, and transition across billionths of a metre in length scales to understand materials properties at each level.

Discovery can lead to intellectual property (IP) that can create new revenue streams, jobs and economic growth. Leveraging IP rights for competitive advantages in a market is therefore essential. Advances in quantum computing hardware hold high commercial value, cathode and electrolyte compositions (often performance-limiting) in lithium-ion batteries are well-kept secrets, materials are at the heart of the patent landscape to desalinate and purify water, and IP remains a key issue for cleantechs to raise capital.

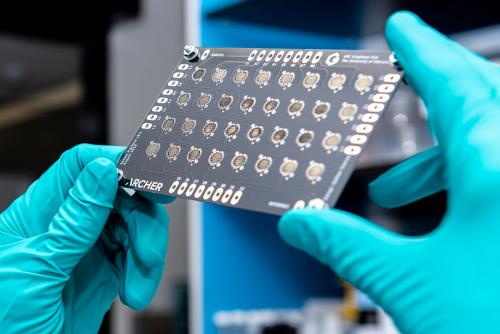

The qubit processor chip

Materials that enable quantum information processing could transform all industries that depend on computational power and are at the heart of some of the biggest challenges in quantum computing. The quantum computing industry represents a rapidly growing sector in the more than US$500 billion market of the global semiconductor industry. Using materials to process quantum information could lead to the design and synthesis of new materials (e.g. better catalysts, drugs and pollutant absorbers) that can turn the materials economy into a positive, virtuous feedback loop.

Limitations on the practical working conditions of quantum computing processors (qubit processors) are imposed by the operating temperatures required to coherently control quantum states in materials components and integrating these materials into modern devices. Currently, all qubit processors either only work at extremely low temperatures or are very difficult to integrate into modern electronics (or both). Materials’ advances towards practical quantum computing represent potential multibillion-dollar economic drivers.

At Archer, we are building a qubit processor chip, dubbed 12CQ, that has the potential to operate at room temperature and be easily integrated into modern electronic devices. We are using unique carbon nanospheres to store and process quantum information using the quantum property of electron spin. I co-invented the technology that resulted from the underlying discoveries during my Fellowship at the University of Sydney in the School of Chemistry, together with colleagues at EPFL (Lausanne, Switzerland).

By coherently controlling the quantum state of the electron spin at room temperature without the need for isotopic engineering, spin dilution, cryogenic temperatures, well-defined crystal structures, photonics, or the use of metals, many of the technological barriers to realising practical quantum computing using solid-state materials are reduced.

Archer is not a ‘university spin-out’ – the company has been listed on the Australian Securities Exchange since 2007, and now provides the public exposure to financial returns from innovative technologies, such as quantum computing, and the materials that underpin them.

In less than 12 months, Archer has begun assembling the first materials components of the 12CQ chip. Recently, we positioned a single nanoscale carbon-based qubit component on silicon with nanoscale precision. The qubit component is produced from naphthalene, which is derived from oil and gas feedstocks. Directly positioning individual qubits is a key requirement for building a scalable 12CQ chip, and scalability is a key requirement for successful commercialisation. The work to build the 12CQ chip continues at a rapid pace.

Quantum value beyond hardware development

Quantum computers employ the quantum phenomenon of entanglement that makes them useful. This allows the fields of chemistry and materials science to go beyond the limits of complexity that can be achieved through simulations on classical computers, especially in areas relying on strong electron correlations. However, current quantum computers are error prone and require error-correction routines, which in turn require more qubits.

Chemists, therefore, have value to add beyond hardware development. This has been in devising algorithms that run in the error-prone regime to find something useful to do with today’s quantum computers. They are making an immediate impact using several quantum computers to find molecular ground (Peruzzo A. et al. Nature Commun. 2014, vol. 5, p. 4213) and excited states (https://arxiv.org/pdf/1910.05168.pdf), and in exploring the properties of materials, even with only four qubits (Kandala A. et al. Nature 2019, vol. 567, pp. 491–5).

New ways to use and store energy

The global, multibillion-dollar Li-ion battery market is continuing to grow, with growth concentrated in the Asia–Pacific region. Li-ion battery devices service several growing market segments where high-power density and long lifetimes are required at ambient and near-ambient conditions, including electric vehicles.

The potential for widespread consumer adoption of electric vehicles depends on reducing the relatively high cost of batteries compared to oil and gas. The trade-off between cost and battery performance can be addressed fundamentally by a two-pronged approach: decreasing costs by using cheaper materials, efficient processing, and efficiencies of scale; and improving battery performance through effective materials and formulations.

Critical minerals are materials that play an integral part in battery compositions. The prominent technologies for automotive applications include cathode chemistries of lithium–nickel–manganese–cobalt, lithium–nickel–cobalt–aluminium, and lithium–iron–phosphate. Improvements in the anode are centred on using graphite with high structural quality and purity, and an appropriate particle size and optimal morphology for effective Li-ion intercalation chemistry.

The Australian government released its Critical Minerals Strategy (2019), presenting a multi-billion-dollar market value of Australia’s critical minerals. It makes good sense economically to secure materials technology supply chains through mineral exploration. Archer has a broad-scope tenement portfolio to access critical minerals in Australia, including graphite, manganese, cobalt and nickel, and more. Archer has a mining lease for a Li-ion-battery-ready graphite resource in South Australia; however, there are no graphite mines currently operational in Australia.

Li-ion batteries could help reduce emissions from power generation; for example, by integration into renewable energy systems, including wind and solar. However, Li-ion batteries are not an all-encompassing solution to reducing emissions from direct combustion sectors. It is still expensive to use Li-ion batteries in these technologies (a prime example is the management of energy supply and use between the grid) without government subsidies. Also, technologies in mining, manufacturing, the primary industries, and transport may not be driven by a scarcity of fossil fuels, but rather be due to consumer demand for new technologies.

A number of critical – even ‘conflict’ – minerals, such as cobalt, are used in Li-ion batteries. Although Li-ion batteries make mobility and sustainability advances possible, they are overshadowed by the environmental damage and human rights abuses in sourcing the raw materials from countries with highly deregulated and exploitive industries.

Biosensing water-borne disease

Safe and readily available water is important for public health. More than two billion people globally use a drinking water source contaminated with faeces, and by 2025, half of the world’s population could be living in water-stressed areas (www.who.int/news-room/fact-sheets/detail/drinking-water).

There are many complex challenges (and opportunities) to achieving the UN Sustainability Development Goal of universal and equitable access to safe and affordable drinking water for all by 2030. These challenges and opportunities include finding materials that can address the large energy requirements of purifying water and reducing the significant capital costs for deploying water purification systems. Materials must be a part of an integrated technological system producing clean drinking water.

Current materials solutions to produce clean water involve membranes and catalysts. Membranes for desalination and filtration are used to separate salt and/or contaminants from water, and catalysts, including photocatalysts, are used to deactivate biological contaminants (which may not be done by filtration) (Shannon M.A. et al. Nature 2008, vol. 452, pp. 301–10). Additive manufacturing of three-dimensional printed materials for clean water production is a potential digital solution to providing ad-hoc solutions to clean water; however, it is not yet at a mature stage of development.

Identifying and quantifying levels of pollutants in water is important in determining any danger in its consumption. At Archer, we are producing printed graphene biosensors that may have the potential to detect water-borne diseases. We have developed processable carborane–graphene inks that are printed into critical biosensor componentry. The digitisation process of graphene – a material that is essentially all interface – allows us to work towards developing an efficient point-of-use solution to disease detection.

High-tech devices for cleaning water, such as carbon-nanotube-based filters, membranes made from block polymers, and bioinspired membranes, may be commercially ready in the future; however, the availability of clean water in many regions of the world is a problem today. Low-tech materials solutions manufactured at point-of-use may hold the key to widespread utility for now; for example, the use of terracotta filtration devices developed by Potters for Peace, and Kanchan arsenic and pathogen filters made from sand.

Creating new business models

The chemical and physical transformation of raw materials into functional forms is creating opportunities for value and positive financial impact in global markets. There is a need for business models that can better adapt to the growing complexity of risk presented by disruptive materials technology. Fast-paced technical progress at all stages of the materials lifecycle is facilitating the deployment of capital, which requires a careful distribution of financial risk between private and public institutes.

More than two dozen of the world’s leading companies from heavy industry and chemicals sectors (i.e. aluminium, steel, concrete and chemicals manufacturing etc.) have set themselves science-based emission-reduction targets (sciencebasedtargets.org); and in Australia the total issuance of Green Bonds (debt raised specifically for environmental purposes) reached $15.6 billion last year (www.climatebonds.net), while The New Plastics Economy Initiative, convened by the Ellen MacArthur Foundation (www.ellenmacarthurfoundation.org), has brought together more than 400 companies to help eliminate plastic pollution and waste.

Only dynamic and nimble regulatory systems can support and oversee truly disruptive and revolutionary technologies. To develop and reach effective regulation, a transparent and conscientious consideration of human safety and the environment is needed at every stage of the materials lifecycle. A systemic view is required in the search for new business models, while adequately addressing risks related to the negative impacts on societies by materials that underpin technological progress.

Making connections in a challenging field

Chemistry is a challenging field for advanced materials development. The inflow of talent is affected by a decline in interest, particularly in countries that have well-established capabilities in the materials field. Institutes that segment and silo the physical sciences threaten the increasingly interconnected and emerging industries serviced by materials chemistry that require a new type of talent: chemists who are capable of connecting complex concepts and operating in dynamic workplaces will propel the field.

The chemical and materials industry is a trillion-dollar industry and sectors are developing to help improve global living standards. One of the best ways the industry is contributing to making a positive financial impact is through innovation and collaboration. This is helping define new business models, and to better utilise existing business models, to leverage new materials technology developments for maximum benefit to people, communities, and societies around the world. The strategic injection of capital at various stages of the materials lifecycle will not only help create solutions to securing digital and legacy assets, but will also allow for greater access to energy, clean water, and sanitation, with a promising future ahead being defined by a new materials-centric economy.